Additive Manufacturing

Enhancing metal machining technology: rapid prototyping and versatile design possibilities

AM or 3D printing basically generates three-dimensional objects from a digital 3D-CAD model.

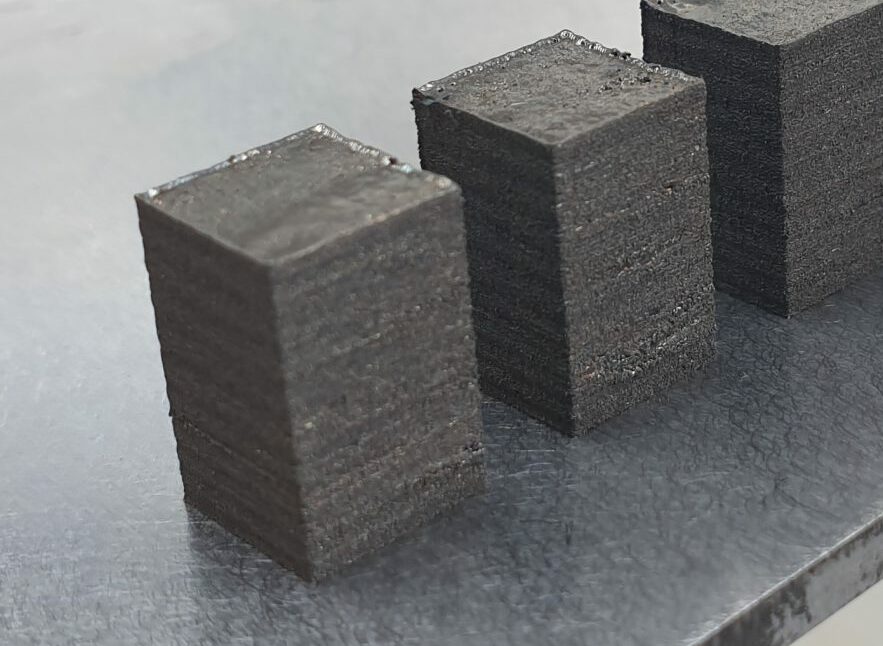

It describes various computer controlled material deposition, joining or solidification processes that create a three-dimensional object adding material layerwise rather than subtracting it like in conventional manufacturing.

The first R&D started in the late 1960s. In 1987, Stereolithography (SL), the first commercial AM application solidified thin layers of UV-light-sensitive liquid polymer with a laser.

In 1997, the first commercial 3D printing process was reported by selectively melting titanium alloy powder layers.

Additive Manufacturing Features and Benefits

- Rapid prototyping, rapid tooling, rapid manufacturing, and rapid repair

- Expansion of design possibilities and enabling of unprecentended weight and strength properties

- Near net-shape manufacturing of components and reduction of waste and energy consumption

Additive Manufacturing - Technology

Additive manufacturing with beam technology enables rapid prototyping, tooling and manufacturing of metals.

It is the third main manufacturing principle, aside of formative manufacturing and substractive manufacturing.

Metal Additive Manufacturing can be applied with different technological approaches. Currently, more than 18 different metal 3D printing processes known. Laser-based powder bed fusion is the most common technology. Furthermore, there are wire-feed beam technologies, which offer higher build-rates in comparison to powder bed fusion.

For fine and complex structures the powder bed fusion is the preferred choice for metal additive manufacturing.

For high deposition rates and simpler structures, wire-feed offers the most suitable approach.

For sheet layer stacks of different materials such as metal ceramic sandwiches, diffusion bonding serves best.

Our Scope of Applications

Additive Manufacturing - Systems & Options

Different technologies in a vacuum for optimized additive manufacturing

Additive Manufacturing - Additional Information

In the metalworking environment, 3D printing represents a significant change of paradigm. This technology enables complete different approaches towards manufacture of items, which could make a number of production process steps of traditional manufacturing methods obsolete: e.g. casting or machining.

Features and benefits

- General approach:

3D printing technology utilizes digitalization for fast conversion from data into structured material.

A virtual 3D-CAD model is converted into a real-life 3D component directly with a machine for additive manufacturing. In addition, computer-aided design can be rapidly changed and a new 3D item can be built.

- Rapid prototyping:

Focus on fast generation of a prototype for demonstration purposes, i.e. look and feel. No high requirements regarding material properties nor strength.

- Rapid tooling:

Parts or items for real usage with high requirements towards the performance (material properties, strength, etc.).

- Rapid manufacturing:

Direct manufacturing of customized production of small series in near net shape based on the computer model.

- Rapid repair:

Direct application of material at damaged area in near net shape.

- Near net-shape manufacturing of components:

3D printing works layer-by-layer and achieves a near final net-shape is achieved with a minimum of material.

- Enabling unprecedented weight and strength properties:

3D printing of metallic materials enables unusual or complex geometries, which maintain stability while decreasing weight. Examples are: inner structures like load-optimized, bionic architectures (e.g. honeycombs) or inner channels for cooling fluids. Components can be manufactured as one piece instead of as an assembly of several sub-components.

- Reduction of waste and energy consumption:

Additive manufacturing has a double impact on the environmental footprint.

Direct impact in production: across the complete process chain, 3D printing directly builds up only the essential structures, which saves energy and reduces the post-processing effort as well as waste.

Indirect impact in the life cycle of 3D printed parts: these parts can be lighter than convential parts. Especially for vehicles and aircrafts, weight reduction consumes less energy. Furthermore, when at the end of the life cycle, the 3D printed part has less material to recycle or to dump.

Challenges of additive manufacturing

Despite the positive aspects of additive manufacturing for rapid prototyping, the possibilities for completely replacing conventional machining in large scale production are limited. This applies for metal 3D printing for various reasons. This situation is dynamic and subject to change.

- Material consistency of manufactured workpiece:

The consistency of each plane of layer may not be uniform when applying 3D printing with its layer-based material build up. As technology progresses, this aspect might get close to conventional production methods.

- Mechanical restrictions of workpiece size:

Currently, the achievable sizes of 3D printing do not comply with certain requirements of industry segments like aerospace.

- Material cost:

Especially the costs for metal powder are high compared to conventional manufacturing. This is currently caused by a narrow group of suitable metal powders and lack of scale effects.

- Scalability:

The build process of additive manufacturing with metal is time consuming and depends on the individual build-rate or deposition rate per technology. The throughput per machine cannot be easily increased to adapt to demand. Conventional manufacturing methods are often more cost-efficient for high-volume production than metal additive manufacturing.

- Mixing of materials:

The conventional metal manufacturing technology offers a wide range of material combinations. These improve or adapt the material properties of the final workpiece. 3D printing with metal currently does no provide this in a economical feasible way in comparison with conventional production.