Rapid Beam Processing in Vacuum

Systeme und Dienstleistungen für

Strahlbearbeitung und

Additive Fertigung

Evobeam

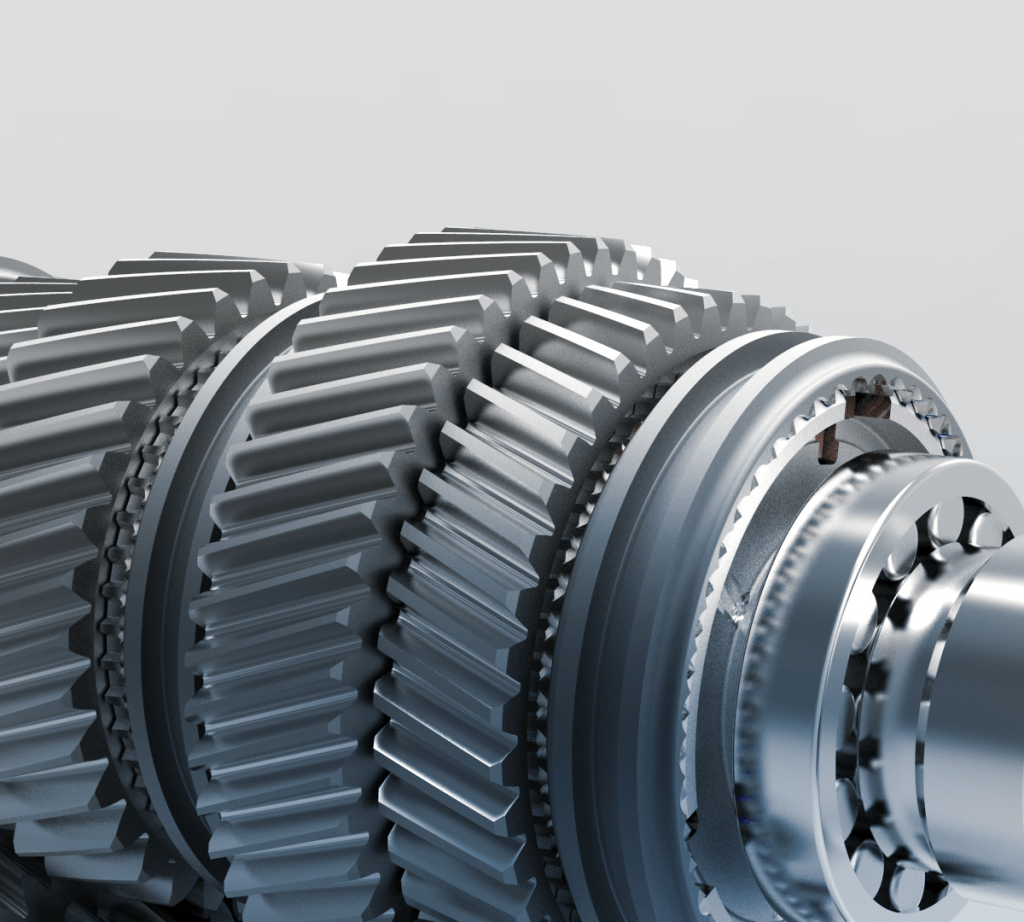

Breites Spektrum unterschiedlicher Systeme und Dienstleistungen für die Strahlbearbeitung.

Performance und höchste Verfügbarkeit unserer Maschinen und Systeme optimieren die Produktivität:

Rapid Beam Processing in Vacuum

Wir unterstützen Sie vom Entwurf bis zum Produktionsauslauf mit umfassenden Dienstleistungen und Expertise:

Unsere Expertise in Metallurgie und Strahlbearbeitung unterstützt Sie beim gesamten Produktionsprozess.

- Prozessentwicklung

- Produktionsunterstützung

- Prozessqualifizierung

- Werkstückgestaltung

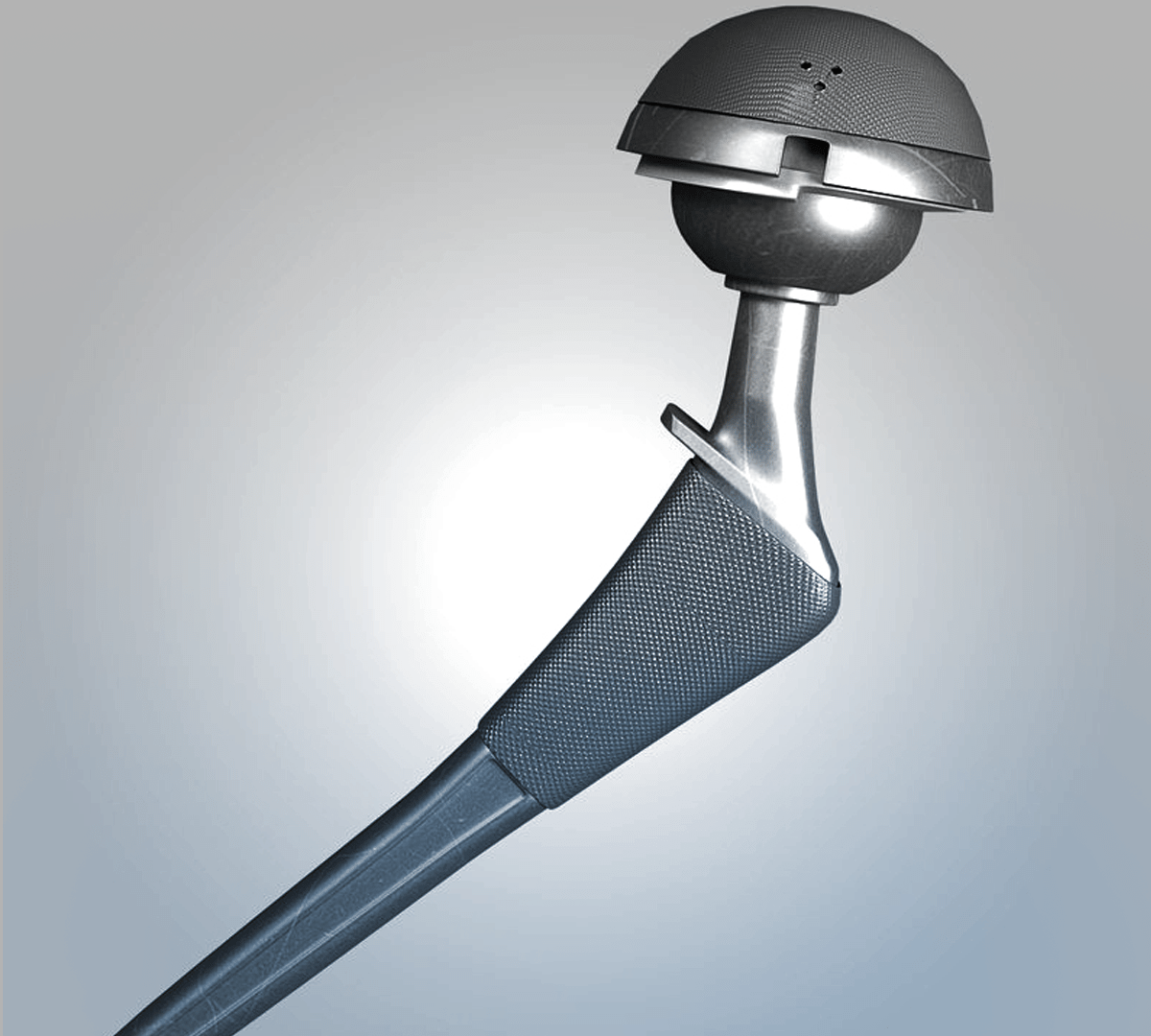

Wir sind ein EB-Schweißdienstleister mit zertifizierten Fachleuten und fundierten Kenntnissen in Metallurgie und Schweißtechnik.

- Schweißzertifikate

- Schweißtechnische Fähigkeiten

- Testen & Prüfen

- Verfügbare Prozesse

Wir unterstützen Sie bei der Bedienung und Wartung Ihrer Anlage für höchste Produktionszeitverfügbarkeit.

- Ersatzteile

- Schulung

- Fernservice & Service vor Ort

- Reparatur

- Wartung

- Nachrüstung